The Ultimate Guide To Preventative Maintenance Program

In a commercial HVAC business, preventive maintenance (PM) is all about building successful systems that allow you to maintain customers and perform at a high level of service.

When thinking about the ultimate guide in your business to preventative maintenance, there are some key steps that are vital to its success. With the correct job management software you can effectively reduce equipment downtime and increase productivity. For your preventive maintenance schedule, there are many factors to be considered from quoting to structuring work. Essentially all this depends on how your maintenance schedule is set up and how it is incorporated into your business.

When you’re diving into your preventive maintenance tasks, you need to have a great maintenance software under your belt as a paper based system can often be more cumbersome and slower.

For an example of a preventive maintenance checklist in practice, check out our Air Compressor Checklist Guide.

The Guide to a Preventive Maintenance Program

Workflow starts here for the Scheduler

- Customer Requests a Quote

The start of a maintenance contract begins typically with a customer requesting a quote. Capturing your customer’s information and goals in this step is vital for efficiency throughout your maintenance process.

In your preventive maintenance quote workflow, it is important that you are able to build a repeatable system for your team to follow. With checklists/playbooks for your team, you can ensure the work is being executed the same way every time (with room for you to constantly improve this process).

You want to ensure that your customer feels like they are being listened to and their goals are being heard. In this first step, you want to take your customer through the process from start to end and ensure they are on the same page. With the assistance of a field service automation guide, you can start your project and incorporate BAMFAM (Book A Meeting From A Meeting) so you don’t miss a beat in your workflow.

2. Data Collection

In your second step, you need to capture core data for your work orders such as; asset type, facility location, asset history/age, serial number, model number, warranty details and customer details. Before you send out your quote, you want to have all the necessary details in your hands so you aren’t surprised by unexpected costs due to bad/no investigating.

With HVAC field service solutions and automated software, it can be a time and money saving tool to have easily searchable information. With a preventative management software, you can log all your customer and asset details to ensure your technicians are equipped with all the information they need in the field.

3. Investigation of site

With all your information stored with the assistance of field service automation, all you need to do next is ensure any extra details are obtained. This includes identifying any safety precautions that may need SWMS and some extra planning on your behalf. Do you need access codes to get on site? Are there people that need to be contacted before you get on site?

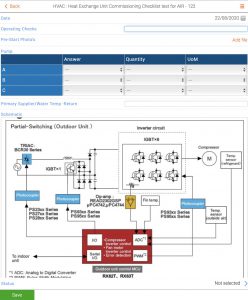

HVAC Checklist – Job Management Software

4. Collation of Number of Assets

Do you know how many assets are in your customer’s facility? A mistake here could see you sending one technician out to site when in reality two were needed and this can become very time consuming. Having a scope on how many assets you need to service is a simple but important step in your planning.

5. Collation of type of assets

Once you know how many assets you have, you need to gather information on what type of assets they are. With HVAC asset tracking you can keep your equipment data streamlined and available when needed. This is another simple but fundamental step in your preventive maintenance program.

Keeping track of your PM plan and asset work orders can allow you to build a specific test for each asset type that can easily be repeated. When you can define what type and how often servicing needs to be done for an asset, you can increase your maintenance management and use this information for future servicing.

6. Understanding access and estimated hours per test

Now you know the type and number of your assets, you need to test and measure the amount of time servicing maintenance tasks will take. This will help you understand your requirements for serving whether that is; weekly, monthly or yearly.

Having a thorough knowledge of the amount of time and complexity of each of your PM tasks will help make sure that you aren’t over or under estimating in your quoting.

7. Understanding testing across multiple periods each with their own hours estimate

When preparing your quoting, you want to be able to stay competitive but also profitable. This also means that you need to understand any additional time requirements in the long term for your PM schedule (any three monthly, bi annual or annual requirements and schedule them accordingly).

8. Understanding consumable requirements

Time is not the only regular maintenance task you need to consider in your quoting – materials and defects can also add up in costs for your regular maintenance. Maintenance planning in the field service industry needs to remain flexible in order to identify and track defects in critical assets that may arise (without costing you an arm and a leg).

9. Quoting

Having a flexible and repeatable quoting workflow is often found missing in a preventive maintenance program. In your PM plan, you ideally want to have a system where you can search quotes and view the status of the job from a glance.

If you have a quote that has been stuck in a status for too long, it can be empowering to your PM plan to be able to reconcile what has gone wrong immediately (instead of three weeks down the track).

Quote success falls greatly on the time based efficiency of your team and the ability to meet your asset KPIs. Without this, you will find it hard to win more work and remain profitable.

Working in the Office

10. Getting Customer Agreement

Maintenance schedules don’t solely rely on time based activities for success, and customer cooperation can also be a vital factor. Having a follow-up system here can be extremely valuable in keeping your customers in the loop so they aren’t surprised by unexpected costs your maintenance team may have accumulated.

A digital system is really of benefit here, enabling you to update quotes quickly and have a high stream of communication with your customers in your preventive maintenance program. Some key essentials in your business need to include easy and efficient communication with your customers through reporting, dashboards, portals and invoicing – ideally you want all this to be with minimal admin effort and maximum traceability.

11. Setting up Checklists and Forms

When you have a planned maintenance guide in practice, you can seamlessly access service checklists and templates for your assets. With a flexible digital system, you can continuously improve on your checklists and reduce the amount of double data entry so you can generate customer reports with ease.

To reduce frustration in your preventive maintenance work, avoid using paper based systems that can be hard to update and share amongst your team.

12. Building Asset Register

Building an asset register in your PM program will help ensure success for your maintenance team. With an asset tracking management system, your technicians will have easy access and the ability to flesh out more information in the field.

Having a good maintenance strategy equipped with your asset data will reduce the amount of unnecessary site trips to discover information such as serial numbers or part codes.

13. Setting up Maintenance Plan for Site

You’ve done the hard work, now time for the magic to happen. Once you have gathered all your information you can map out the test intervals needed for your long term plan.

With your preventive maintenance operations you want to now have a good idea of what your servicing will require. With your management software, you can generate your maintenance plan in line with your contract.

Imagine if you could eliminate hours of work with just one click in your management software.

14. Allocating assets to their respective test (job scheduling can be automated in an awesome software like FieldInsight)

Field service management software that has a preventive maintenance program that allows you to build any tests you want as well as add/remove any assets you want in scope. During the life cycle of your customer’s contract you also need the ability to track and monitor any defects that may arise.

15. Allocating a cost to a Planned Maintenance Visit so invoicing can be done very quickly

Having the power to automatically generate the required visits for when the technicians need to book servicing in is a very powerful tool.

The importance of preventive maintenance lies in the ability to view all your upcoming maintenance work orders in one place. With this tool you can schedule out a whole year on one page with only a few clicks (No need for cumbersome paperwork). You can allocate different types of preventive maintenance, any costs or defects and have all this information ready for your technicians to use on site.

16. Allocating Team members when scheduling work (one click scheduling of visits across the contract period)

In this step, you can save 10s of hours every week by scheduling in advance your maintenance team members to specific jobs (Based on their skill set and availability) for maximum efficiency.

When you have a powerful, flexible preventive maintenance program here, this makes this task 100% easier. A preventive maintenance software will also assist you in indicating servicing type needed and present your technician with the necessary checklists.

Job assignment

Next onto Technicians workflow

- Guys/Gals go out and complete the tests as indicated by PM software

Now you have a brilliant maintenance plan set up, it’s on to getting your team out in the field to the jobs you have successfully scheduled in.

Your technicians will see a list of tests against the assets they need to complete and be able to identify any defects raised in that workflow. The goal is to get through every test question to give you a high level of compliance and accountability for your customers throughout your maintenance tasks.

Check out the top tips for field technicians that can save you hundreds of hours each year.

2. Completing Checklists in the field

When you have killer maintenance checklists in the field with simple steps for your technicians to follow you will find you have increased productivity and professionalism in your workflow.

With CMMS software and maintenance strategies in your business, you can design your workflow towards reducing unplanned downtime in equipment and clarify your maintenance operations.

Technician working on HVAC Unit

3. Taking photos and raising any faults or defects

A picture is worth a thousand words and with your maintenance checklist you’ll have information rich reports to track any raised defects. The important key in this step is all about being responsive to customers and showing the thoroughness of your work. This can help build trust and leads to more work.

Read all about CMMS systemisation and apps to use in the field with the 5 Best apps for contractors.

4. Completing all assigned assets

For efficiency in your office, you need streamlined systems in place that are going to give your admin team the ability to view all completed and uncompleted work – Helping bring more accountability into your workforce and stopping anything slipping through the cracks. With detailed information available through digital copies, you reduce delays in getting information back to your customer.

Now Back to your Scheduler

- Scheduler can view status of work all tests for an interval (Monthly, Quarterly, Bi Annually, Annually)

When you create a preventive maintenance program to schedule your upcoming work, you need to have high visibility over your work for your whole team. A powerful tool to have under your belt is a visual calendar of all upcoming servicing so any details that need to be fixed or chased up are able to, without being forgotten about. Creating this high level of communication within your team is a guarantee recipe for success for any HVAC business.

2. Complete reports of all Asset Information (As a Summary or as a Detailed Report for All Assets and Defects Identified)

When you have a preventive maintenance program that follows this process and you have a good preventive maintenance software in place, you’ve already done most of the work.

With a CMMS program like FieldInsight, you can use the data you have worked hard to gather and generate reports with only a few clicks. This is a massive time saving task and can make a difficult activity much easier for your whole team.

Asset test questions

3. Invoice Monthly as work is completed

What good is it doing the work if you forget to send the invoice for it? Having the power to automatically generate invoices will save your team costly admin time and a lot of double data entry.

If you have a system in place where you can generate the costs of your monthly invoicing for each job, you can be ready to send off documents to your customers with only a few clicks. By having invoicing in check, you can ensure that your cash flow remains balanced and you get paid on time.

For the best accounting practices check out the 7 best HVAC tips.

money and paper flying around

4. Renew Contract 2 months before the contract date is wound up

Don’t wait until your contracts have expired before you think about renewing them. Part of your preventive maintenance plan should include preparation of your contracts prior to their expiration. Letting your customers know 2 months or more before the end of your contract, is a great way to generate more work and keep healthy customer relationships.

Another part of keeping your customers happy in your preventive maintenance plan is getting your quotes in on time and performing with a high quality to improve your contract conversion rate. Basically, if your customers are happy and know they are being taken care of, they are more likely to jump on board when the time comes to renew a contract. This also applies in how you interact with your customer throughout your preventive maintenance history, if you let your customer know a piece of equipment has a defect and you have the reports and data to back you up, they will know they are in good hands.

Getting to your contracts before they expire will also prevent maintenance gaps in your workflow as you wait for a customer to sign back up (causing interrupted cash flow for you).

5. Update Contract Quote for next term

The next step in your preventive maintenance plan will support your renewal workflow. Unlike a reactive maintenance plan, a preventive maintenance plan will allow your customers to flawlessly shift from their old contract to a new one without any interruptions. When you can move all assets across to the new contract and schedule the starting dates – You save yourself a big headache and a lot of double data entry when you have a CMMS like FieldInsight up your sleeve.

6. Send Quote out to Customer

Now this guide has circled back to where it started in your workflow, quoting. In this step, you build a quote with the important factor in mind to review past performance.

As a way to plan for the future, the best way is to stop and review your past preventive maintenance plan and quoting to see what worked and what didn’t. You may find here that last time you scheduled too many technicians for a small job or misquoted how much a replacement part would cost.

Reviewing your preventive maintenance tasks is a key step in moving forward with the right intentions and information, before you quote with the same mistakes again. Losing money here can be all too easy if you don’t have an effective preventive maintenance plan and profitability will fly out the window.

7. Renew Contract

With all the information you have collected already, imagine how easy it would be if you could regenerate the next contract, schedule the dates, get the asset information and all with a few clicks. This is actually a brilliant feature of FieldInsight, a CMMS software that will reduce the unscheduled downtime in your contracts and ensure your customers feel in the loop.

8. Back to the beginning and run again

The bottom line of this preventive maintenance checklist is, you can repeat this process and continuously improve your workflows until you have aced it.

Incorporating a preventive maintenance software into your business may seem overwhelming at first, but the key is to take the elephant one bite at a time. Doing this one step at a time will dramatically reduce complexity, reduce risk of failure and improve your chance of success.

Your preventive maintenance tasks don’t have to take up long office hours and drive you crazy. With the right preventive maintenance programs in your business, it can help you achieve the excellence you’ve been striving for (and save you some time and money along the way).

FieldInsight and YOUR Preventive Maintenance Plan

The best way to enhance your preventive maintenance program is with a killer automated software like FieldInsight.com. With FieldInsight you can turn your reactive maintenance program into a preventive maintenance plan and get started with success in your business.

Don’t neglect your long term PM plan, with a CMMS automated software, you can work on impressing all your present and future clients with critical equipment management and your impressive maintenance scheduling.

With the ability to use your PM program in real time through FieldInsight, your technicians will have all the tools they need to adhere to manufacturer recommendations, reduce unplanned downtime and boost your maintenance strategies.

Don’t keep stressing over high maintenance costs and run to failure, Book your Demo today with FieldInsight and find success in your business.

What You Should Do Now

- Book a Demo. You’ll be in touch with an automation expert who has worked in this space for over 5 years, and knows the optimal workflow to address your needs.

- If you’d like access to free articles about managing HVAC workflows, go to our blog.

- If you know someone who’d enjoy reading this page, share it with them via email, Linkedin, Twitter, or Facebook.